Step-by-Step Guide to How to Implement PDCA and Add Quality to Everything You Do

Por Aécio D’Silva, PhD(1), Maécia Moura, MSc(2), Fabiano Moura, MSc(3)

(1) Moura Enterprises, AquaUniversityTucson, AZ 85742, EUA; (2) Signature Dental Partners, Phoenix, AZ 85008; (3) Profound Commerce, Inc. Austin, TX 78746.

Have you encountered a persistent problem/challenge that remains unresolved despite several attempts? Can you remember all the strategies you’ve tried? How much time did you spend defining the problem? Do you have a clear understanding of the challenge at hand and the process that requires correction? It is possible that the root of the problem lies in the absence of a challenge/bottleneck resolution methodology.

Implementing PDCA – How about using the PDCA methodology in problem solving? You will be amazed at the efficiency of the PDCA tool-process of continuous improvement in solving the day-to-day challenges of your business and tasks!

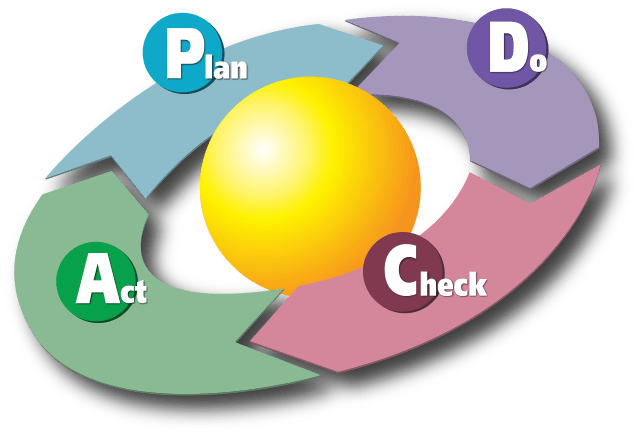

The PDCA (Plan-Do-Check-Act) cycle is a powerful tool for continuous improvement. In this article, we’ll explore practical examples of how to apply the PDCA cycle to improve your product or service, with a step-by-step guide to help you get started.

Continuous improvement is an essential part of any successful business and LAQLS Way Quality Leadership Management. The PDCA cycle is a simple but effective tool for continuous improvement. The PDCA cycle comprises four stages: Plan, Do, Check, and Act.

PDCA helps companies identify problems, develop solutions and continuously improve processes, products and services. In this article, we’ll explore practical examples of how to apply the PDCA cycle to improve your product or service, with a step-by-step guide to help you get started.

Implementing PDCA – How to Apply the PDCA Cycle to Improve Your Product or Service

The following are practical steps to apply the PDCA cycle to improve your product or service:

Step 1: Observe and Plan

The first step in the PDCA cycle is to look closely at the current reality, paying close attention to the details. Observing is so important that there is a version of PDCA, called OPDCA, where the O is placed as the initial in phase of the cycle. Once careful observation has been made, it is time to plan. In this step, you need to identify the problem or opportunity for improvement. You should also define your goals and objectives, collect relevant data, and analyze the root cause of the problem. Once you’ve identified the problem, you should develop a plan for improvement.

For example, if your product is a mobile app, you may have received customer complaints about the app crashing frequently. You can collect data about when crashes occur, the types of devices affected, and other relevant information. Analyze the data to identify the root cause of the problem, which may be a specific function within the application. You can then develop a plan to improve the function and prevent future crashes.

Step 2: Do

The second step in the PDCA cycle is to do. In this step, you need to implement the plan. This may involve making changes to your product or service, or it may require training staff in new processes. Always remember to test on a small scale.

For example, if you’ve identified a function in your mobile app that’s causing crashes, you can implement code changes to fix the function. You may need to perform tests to ensure that the changes do not cause new problems. If you need to train staff on new processes, you must provide the necessary training and support.

Step 3: Verify

The third step in the PDCA cycle is to check, analyze, or check. In this step, you need to monitor and evaluate the results of the changes you made in the previous step. You should compare the actual results with your expected results and get feedback from customers and staff.

For example, after you make changes to your mobile app, you can monitor user feedback to see if there are any new issues. You can also collect feedback from the team to see if the changes have improved your work processes. If you have set specific goals for improvement, you should measure the results and compare them to your expectations.

Step 4: Take action

The fourth and final step in the PDCA cycle is to take action. In this step, you need to act based on the results of your assessment. If the changes were successful, you should standardize them and continue to monitor the situation. If the changes were not successful, you should review your plan and start the cycle again.

For example, if changes to your mobile app have successfully prevented crashes, you should standardize the changes and continue to monitor user feedback to ensure that there are no new issues. If the changes were not successful, you may need to review your improvement plan and try again, or discard and try another plan. However, don’t give up on improving, and always try first on a small scale.

Implementing PDCA – The Supreme Importance of the Voice of the Customer

A fundamental principle that should be used when implementing PDCA to improve a product or service is to always listen to the Voice of the Customer. A practical example of this concept is to use customer feedback to identify areas for improvement. Therefore, the first step is to observe and plan, gathering and analyzing customer feedback to identify the most common problems.

Then take action by implementing changes to address those problems, challenges, laughs by identifying how to improve product design or train staff in better customer service techniques. Then check the effectiveness of these changes by monitoring or listening to the voice of the customer coming from feedback from those who use your product/service and measuring the impact on sales or customer retention.

Finally, take all necessary corrective action and continue the cycle by regularly gathering feedback and making improvements. By using the PDCA cycle, companies can continuously improve their products and services to better meet the needs and expectations of their customers.

In summary, the PDCA continuous improvement cycle is a simple but powerful tool for companies to improve their products or services. By following Implementing PDCA, the four steps of the Plan-Do-Check-Act or five of the OPDCA, companies can identify areas for improvement, take action, verify the effectiveness of these changes and continuously implement the improvement cycle. By making continuous improvements, companies can better meet the needs and expectations of their customers and stay ahead of the competition.

References:

(1) Deming, W. Edwards (1986). Out of the crisis. Cambridge, MA: Massachusetts Institute of Technology, Center for Advanced Engineering Study. p. 88. ISBN 978-0911379013. OCLC 13126265.